GREEN & GROWTH®

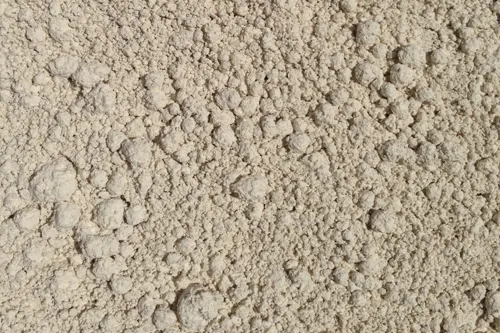

LignoCellulosic Fiber 100% Hemp

Our lignocellulosic fibers are a highly technical and versatile material that is gaining popularity for multiple applications and in different industrial sectors, both for the mechanical benefits they provide to the final products and for their sustainable nature.

APPLICATIONS

Biocomposites

Construction

Paper and Cardboard

Nonwoven Textile

Industrial Absorbents

Nanocellulose

DIFFERENTIATORS

Green & Growth offers different particle sizes for its LCF lignocellulosic fibers, on a micrometer and millimeter scale.

Years of research have led us master our starting raw material and its processing method, making a difference from other natural fibers on the market in terms of:

100% fibers coming from industrial hemp, which guarantee a homogeneous behavior of the material, is reproducible and open to any specific subsequent treatment of each final product to be directed.

Fibers resulting from industrial hemp varieties, selected for their ideal molecular composition (cellulose, hemicellulose, lignin, etc.)

Green & Growth has designed a process which is capable of keeping the structure of lignocellulosic fibers intact at a molecular level.

This process does not use any thermochemical process that involves the use of water or organic or inorganic solvents, but rather it is exclusively a mechanical one.

The molecular arrangement of hemp cellulose microfibrils is unique in the plant world, and is intrinsically related to its unique resistance and elasticity properties.

Cellulose has the natural function of being the structural polymer of all plants. The amount of cellulose and its arrangement at the molecular level varies among species.

The innovative process designed by Green & Growth respects the molecular integrity of the plant, preserving its natural mechanical properties and allowing them to be transferred to the final product.

Some of the molecules, present in the plant, have the natural function of holding cellulose microfibrils together. Hence, maintaining their molecular integrity allows reducing the use of additives for the union of the different compounds in the final product.